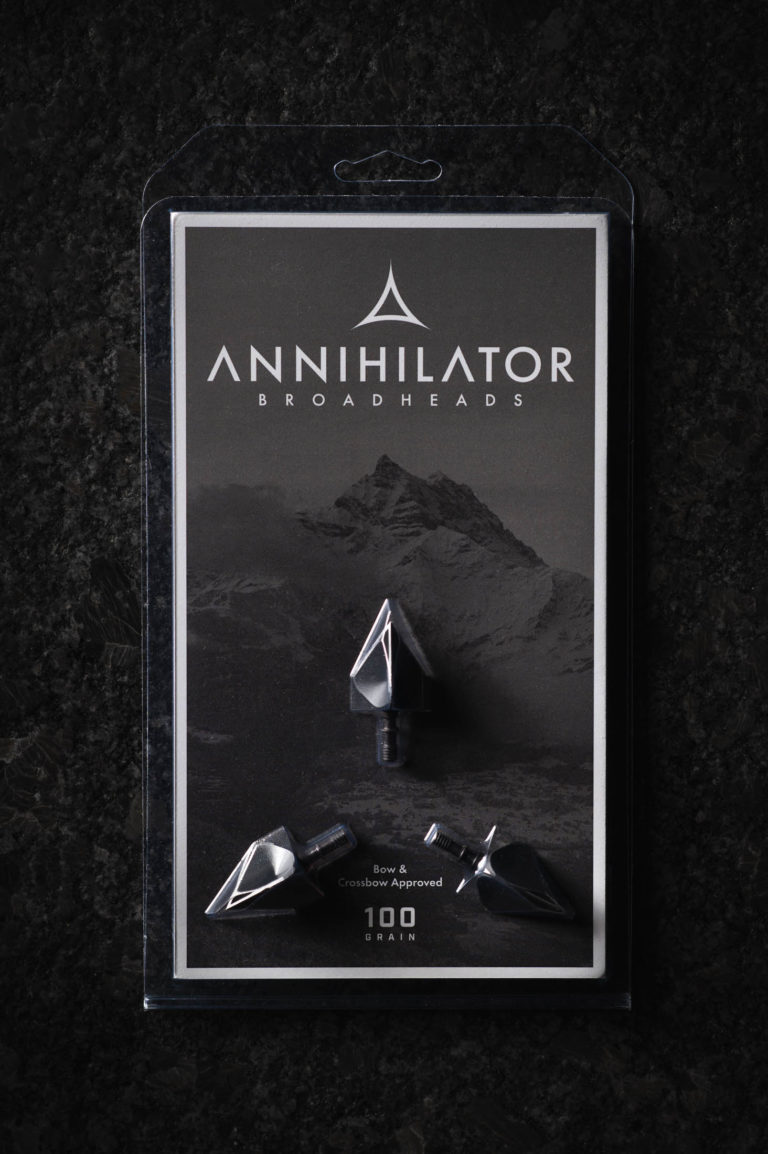

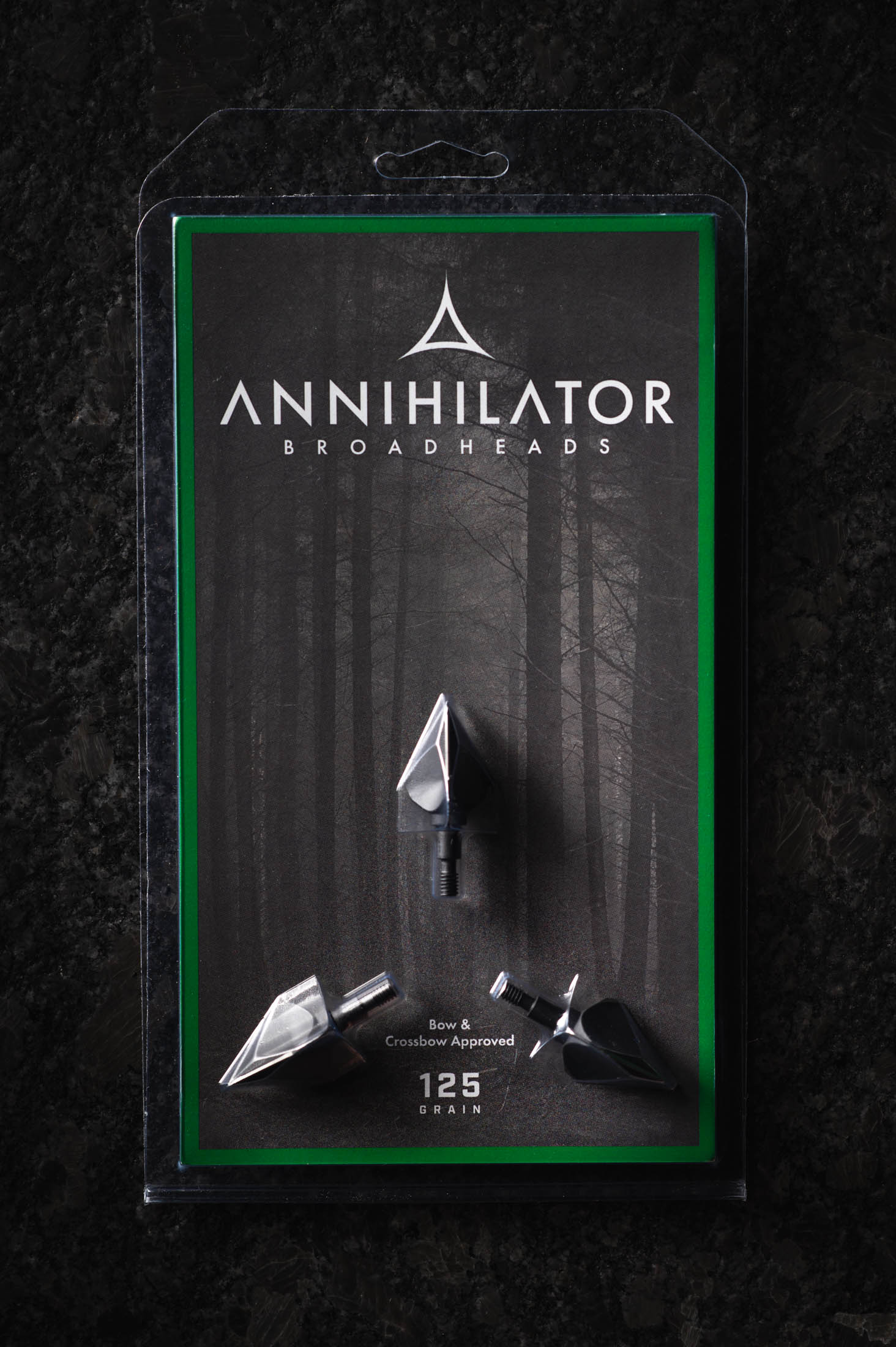

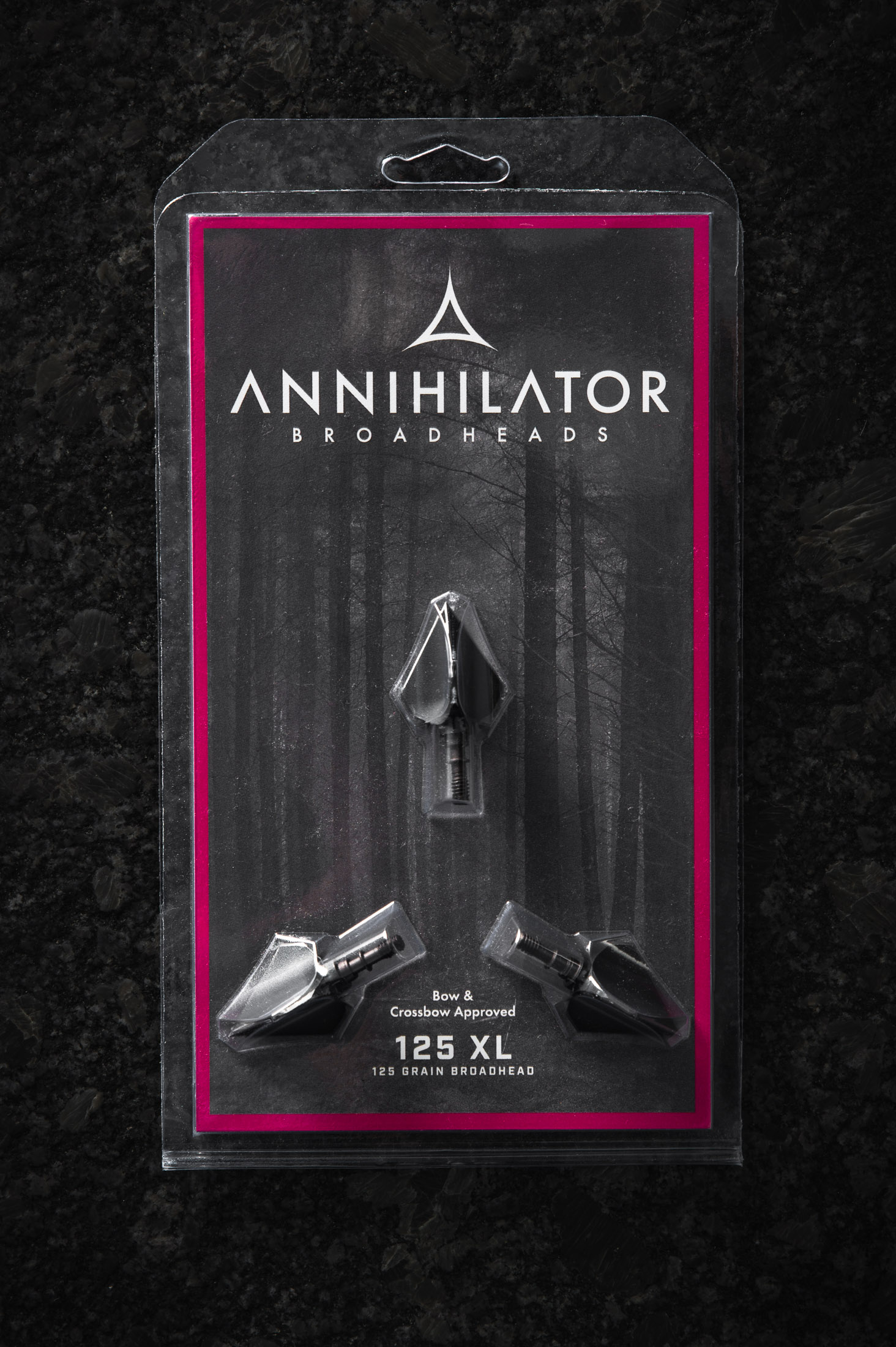

Annihilator 3 Blade Broadheads

59,90 € – 69,90 €

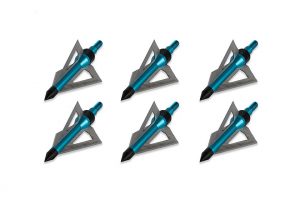

3 Blade Solid

100 & 125 Grain

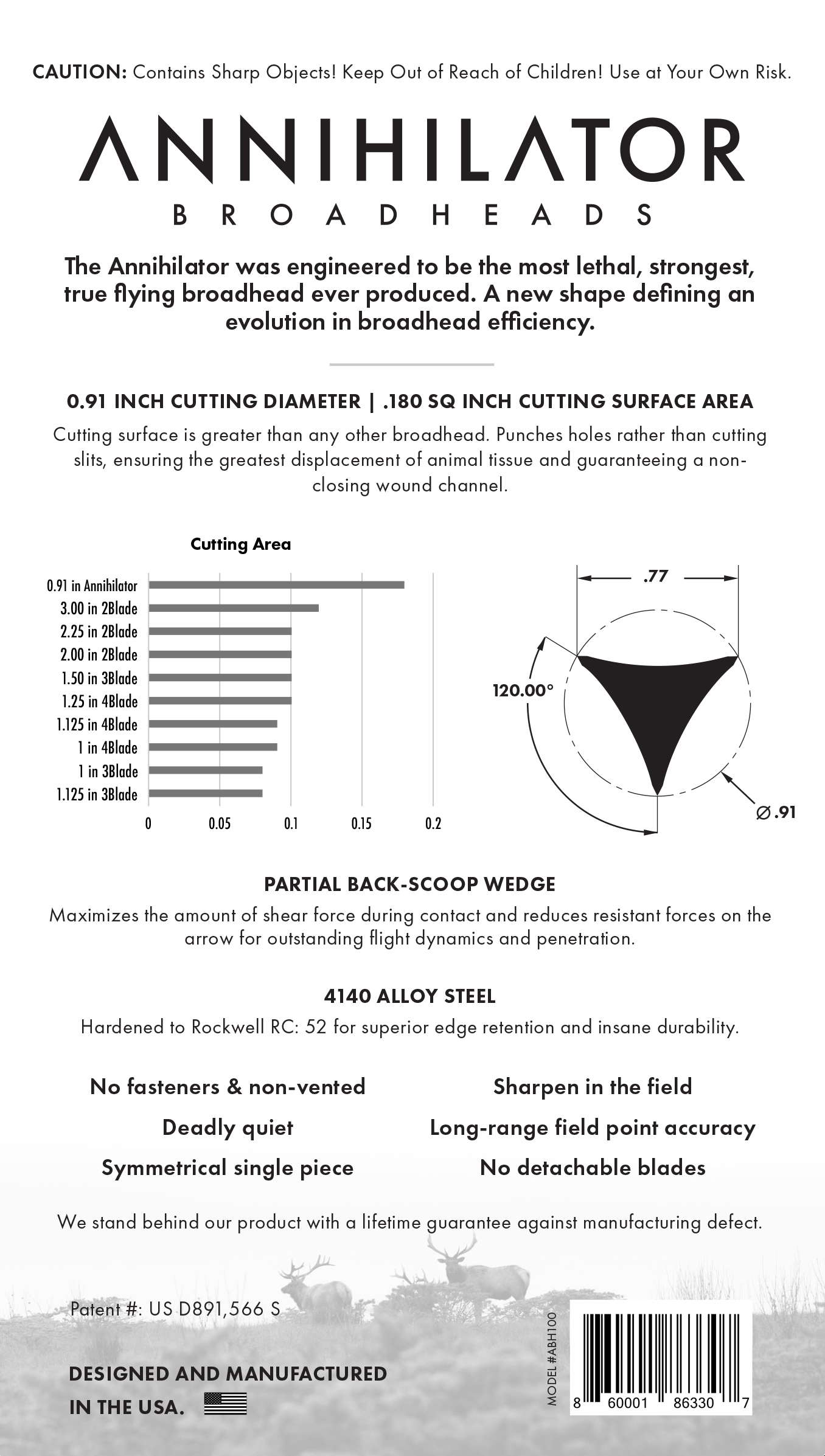

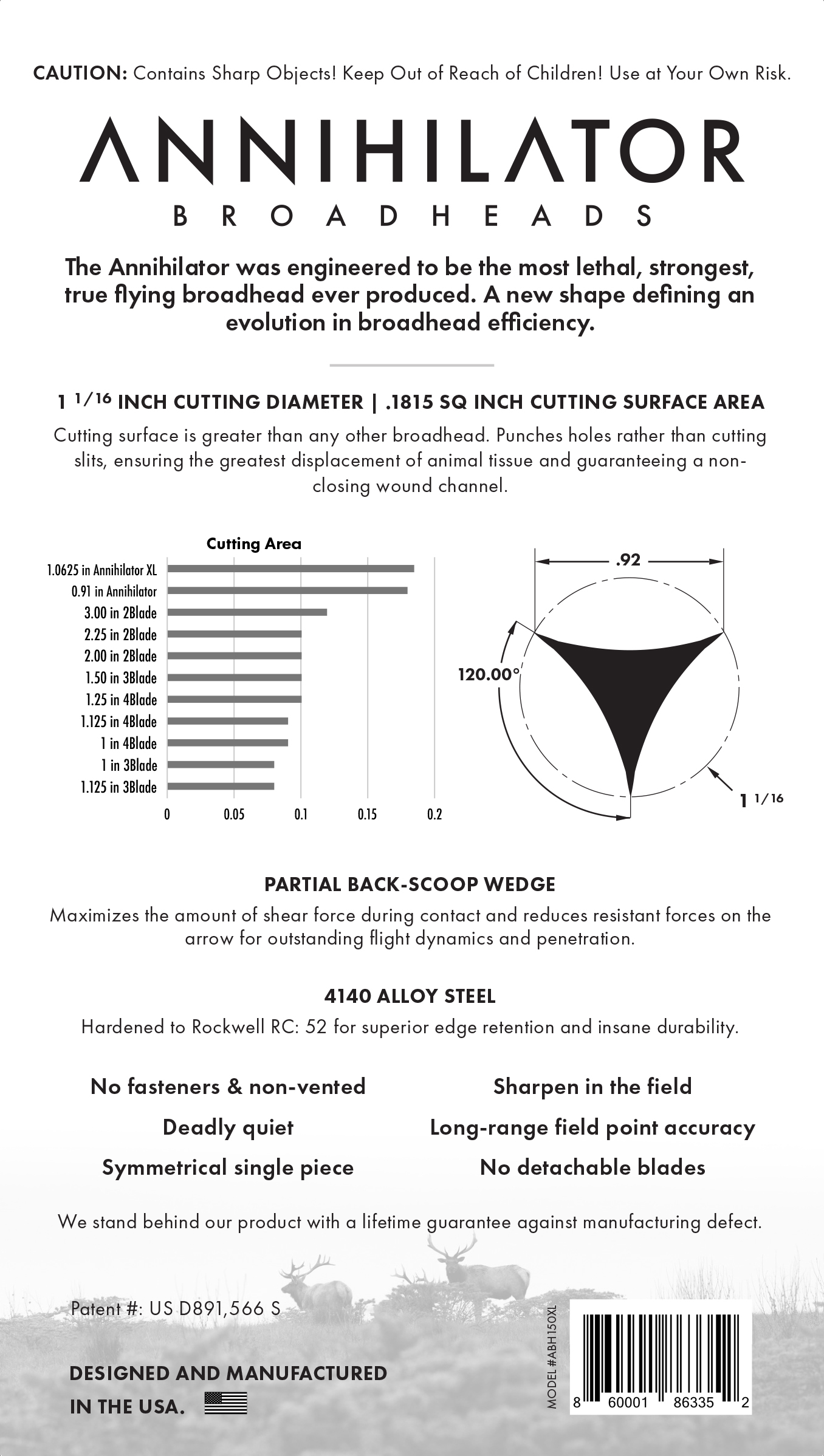

Cutting Surface Area | .180 square inches

Cut Diameter | .910 inches

(The standard Annihilator has the largest cutting surface area of any other broadhead. See chart under product images for more information.)

100 XL, 125XL & 150XL Grain

Cutting Surface Area | .1815 square inches

Cut Diameter | 1 1/16th inches

-4140 alloy steel hardened to Rockwell RC: 52 for superior edge retention and insane durability.

-Can be easily field sharpened flat on a stone and reused.

-Fits any insert / halfsert / outsert system that uses a standard 8/32 thread pattern (Annihilators are not available in deep six)

-Heads are batched within 0.2 grains of each other.

-Designed and manufactured in the USA.

-Lifetime warranty against manufacturing defect.

RECOMMENDATIONS

These are general recommendations. Every setup is different so it’s best to test for yourself and discover what works best for you. Please reach out to us if you need more specific help!

– Annihilator XLs will be slightly more forgiving with shot placements due to the larger cut diameter. They do produce larger holes in animals than the standard size Annihilators.

– Standard size Annihilators should not require much if any broadhead tuning and can be shot with any vane configuration and will also be our highest penetrating broadhead.

– Larger cut broadheads in general require more steering for optimal flight so Annihilator XLs should be paired with fletchings similar to either ~3″ or greater in length or a 4 fletch. No matter which vanes you choose, it’s also a good idea to add a helical and / or offset.

– If you are on the fence about which Annihilator to shoot, the vast majority of Annihilator customers shoot our standard size 100-grain broadhead.

| Size | Standard, XL |

|---|---|

| Weight | 100 Grain, 125 grain, 150 grain |

Deutsch

Deutsch

GEORGIOS N. (verified owner) –